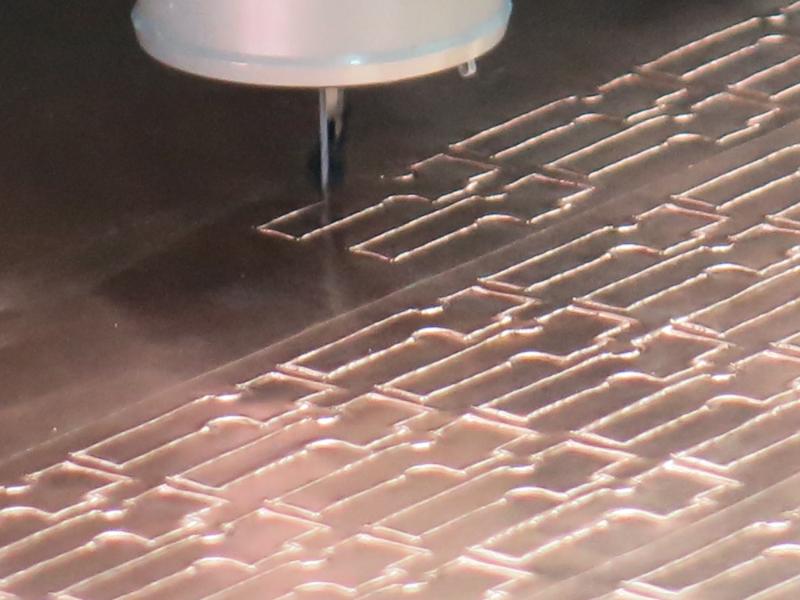

CAD Cutting Machine

This technology enables fast and accurate cutting (tolerance: + -0.004”) of variety of raw materials

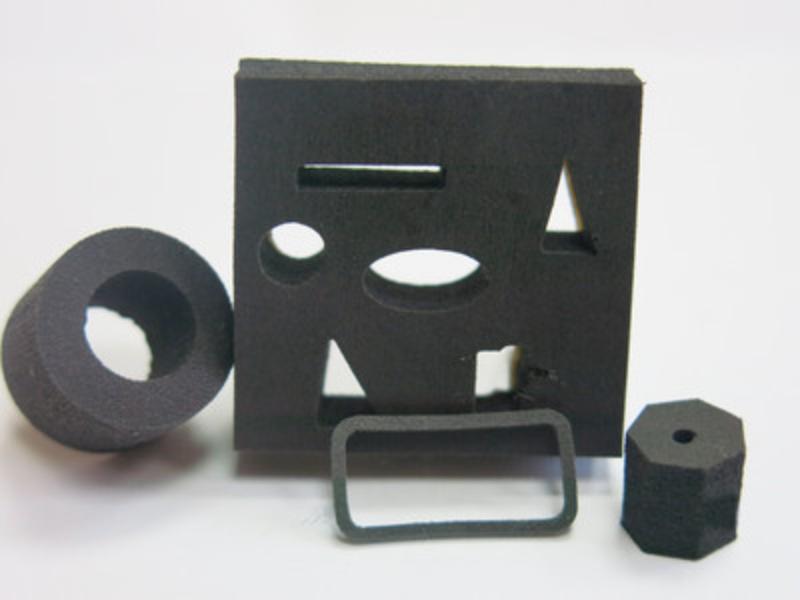

Sponges and seals cutting

We offer cutting of Thin foams ranging from 0.02” to a height of inches. significant use of the advantage in cutting accurate CAD technology is the ability to create exceptional straight (“wall”) is also very thick sponge without the inner curve as used with die cut (photo third from left ), To see example click here

Pads and thermal conduction cutting

Thicknesses ranging from 0.002” to thicker thermal pads produced by manufacturers. CAD technology enables maximum utilization of nearly 100% space utilization of the pad thermal sheet. Those expansive materials usually comes in sheets then this advantage will allow making the price attractive to utilization cavity. To see example click here

Another advantage of this method of CAD technology is the minimum contact material while cutting unlike using of die cutting tool which increases the area clicked between die to material surface which may change some geometry dimensional sizes of the item and the material properties. Since thermal pad materials are extremely subtle and crisp cutting them with a minimum of contact allows obtaining Pad accurate and more symmetrical.

Insulating materials cutting

Thicknesses ranging from 0.0005”and up. Insulation electric especially Terminals are materials with electrical electro – static multi alleged after contact and factors upload them and attracting dust particles .Using Cad technology contact minimum prevents the loading of materials and attracting dust on the scope. Thicker insulation material create a similar problem exists with severe and complex geometries due to the inability to bend knives these forms and use knives especially thick consulting deal with difficult material. Cutting using CAD geometry is not limited Ease complicated and is virtually unaffected by all the difficulty of the material.To see example click here

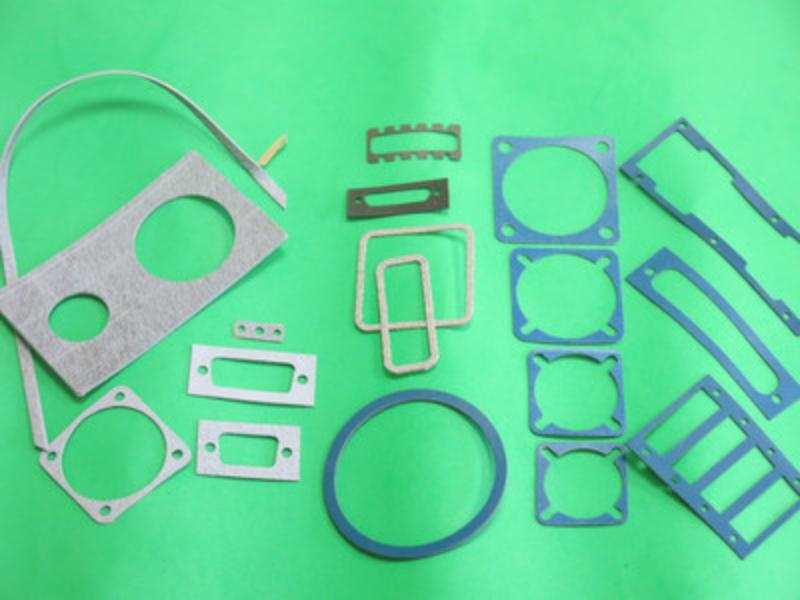

EMI/RFI cutting

As of thickness 0.002” and up. These advanced materials usually composed of various combinations of metals with different fillers such as carbon, silicon, etc. The use of CAD technology is very important to prevent damage to these delicate metals. Another advantage is the maximum utilization of the most expensive raw materials allowing you receiving an attractive price per unit. To see example click here

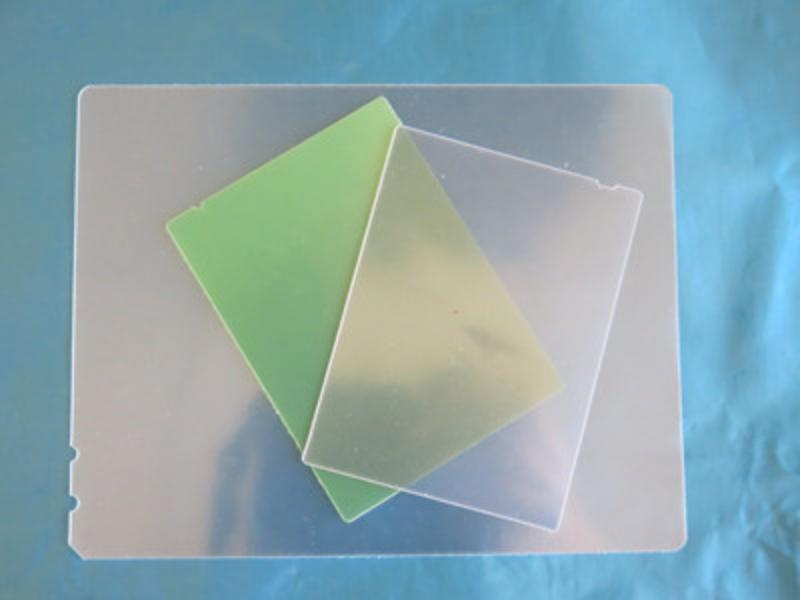

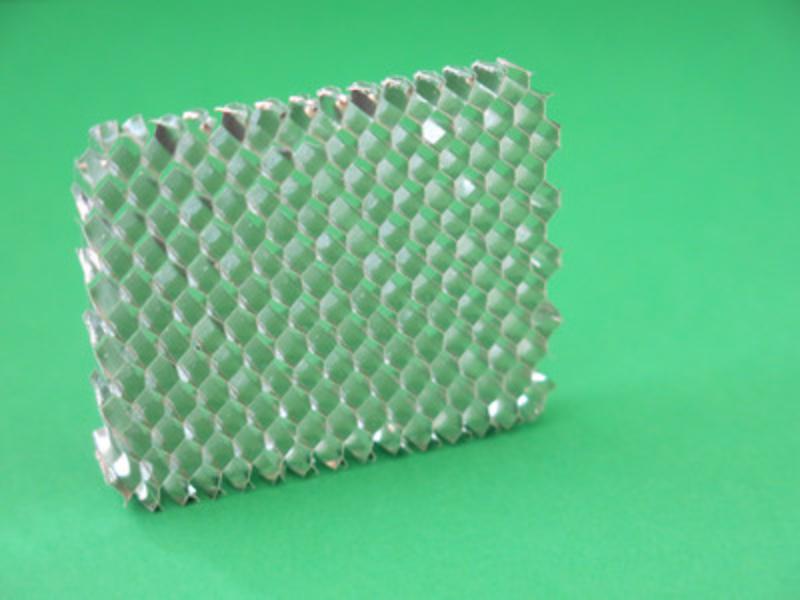

Optical foils & Honeycomb cutting

NVG FILTER , 3M VIKUITY BEF